Did you know the typical American throws away approximately 81 pounds of clothing annually? Or that less than 15% of textile waste is recycled worldwide? In a time when fast fashion contributes immensely to our ecological footprint, textile recycling machines are emerging as unsung heroes in the battle against waste. But how do these high-tech systems transform your worn-out jeans and threadbare sweaters into valuable new material? Why should you pay attention to this technology?

This comprehensive guide dives deep into the fascinating world of textile recycling machinery and how different systems process different kinds of materials—from second-hand apparel and home fabrics to speciality fibres like wool and cashmere. We'll find out the mechanical processes and environmental benefits involved in these machines to make them essential in establishing a more eco-friendly fashion industry.

Fashion is the second-largest polluter globally after oil. Millions of tons of textile waste go to landfills yearly, and practical recycling solutions are more necessary than ever.

Textile recycling equipment is the pillar of circular fashion economies, converting what was once considered waste into valuable raw materials. These sophisticated systems have advanced significantly in the past ten years and can now treat various kinds of fibres with minimal loss of quality.

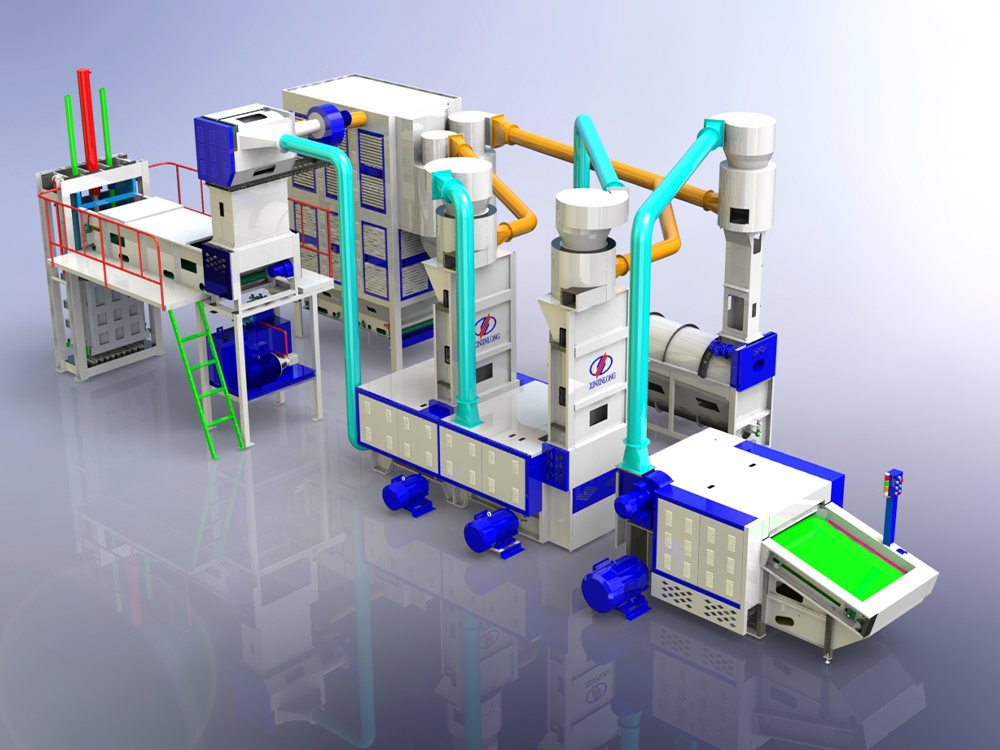

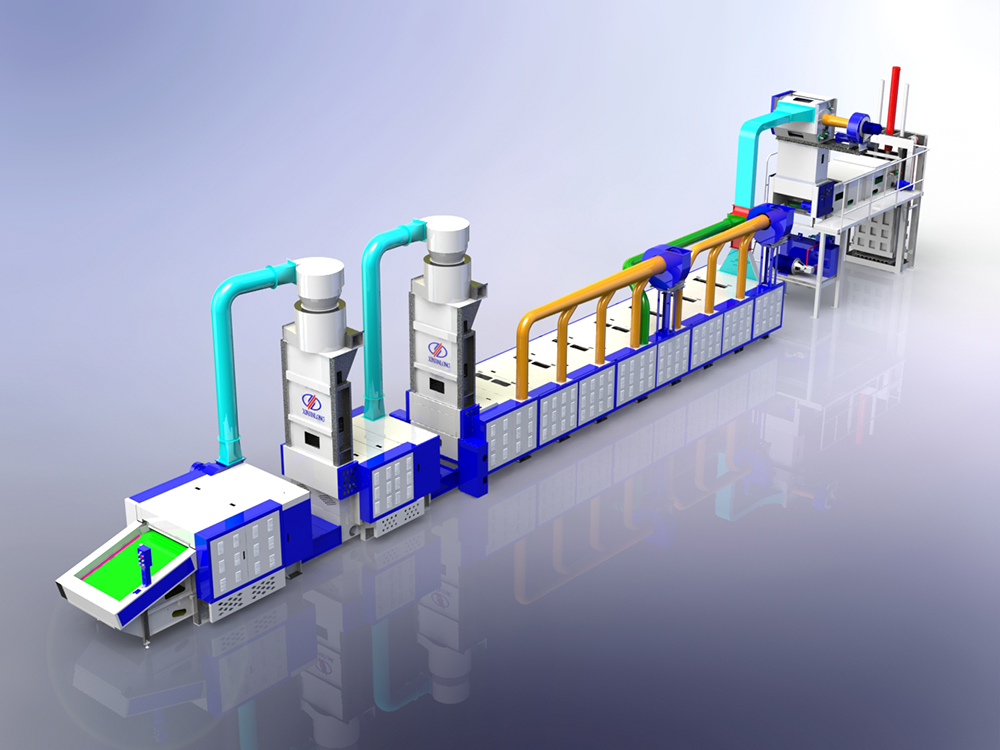

Let us first discuss the fundamental components that are found in most textile recycling equipment before discussing specific recycling lines:

1. Sorting System: Generally combines both manual and automated sorting to sort materials by condition, fibre type, and colour

2. Shredding Mechanism: Shreds materials into fragments using turning blades

3. Cleaning Unit: Picks up non-textile items such as buttons, buttons, and zippers and dust

4. Fiber Separation System: Breaks down material into separate fibers

5. Baling Equipment: Piles processed fibres for storage or shipment

The specific setup relies on input material and output quality, but these core elements are the foundation of most systems.

Have you ever wondered what happens to that donation bin of clothes you left at the drop-off point? This is how old clothing recycling machines convert them into:

1. Initial Sorting: Materials are sorted according to fibre content, and some machines employ near-infrared spectroscopy to determine the types of fibres.

2. Contaminant Removal: Workers or sorting systems remove buttons, zippers, and other items that could damage equipment.

3. Shredding and Cutting: Industrial shredders tear clothing into pieces.

4. Fiber Opening: Specialized machinery manually breaks down fabrics into single fibres.

5. Cleaning and Dedusting: Strong air systems remove dust, dirt, and short fibres.

6. Blending: Virgin stock and recycled material are usually blended to add strength and quality.

7. Carding: Fibers are combed and aligned to a loose rope shape called a sliver.

8. Spinning: The sliver is drawn and twisted into yarn on spinning machinery.

These production lines can handle everything from jeans and t-shirts to bed linens to towels, and as such, they are ubiquitous workhorses within the recycling industry.

Hemp became a recognised green fibre that requires significantly less water than cotton.

Hemp fibre production lines focus on pre-treatment processes:

1.Retting: Breaking down the pectin that holds fibres to the woody core through water-soaking or chemical means.

2. Breaking: Woody cores of hemp stalks are broken by mechanical breakers.

3. Scutching: Spinning paddles separate broken wood pieces (hurds) from the fibres.

4. Hackling: Fibers are combed to remove short fibres and align long ones.

5. Softening: Chemical or enzymatic treatment softens the naturally stiff hemp fibres.

These speciality lines process hemp fibres for spinning into yarn or manufacturing textiles, resulting in naturally antimicrobial and UV-resistant materials.

Wool recycling equipment processes both pre-consumer waste (factory trimmings) and post-consumer products like old sweaters:

1. Color Sorting: The wool is sorted by colour to minimise re-dyeing.

2. Garneting: A teethed machine tears wool products into the fibre.

3. Carbonizing: Acid treatment eliminates Cellulosic impurities from the wool.

4. Scouring: Lanolin, dirt, and processing aids are removed.

5. Drying and Conditioning: Dryness is maintained with care to preserve fibre quality.

6. Blending: Recycled wool typically blends with virgin wool or synthetic fibre.

7. Carding and Drawing: Fibers are straightened and spun into slivers for spinning.

This process can recycle waste felt, shed wool, and carding machine trimmings into new yarns for knitted and woven finishes.

Cashmere, the most valuable textile fibre, requires specialised recycling machinery due to its high value and softness:

1. Gentle Shredding: Special low-speed cutting machines preserve fibre length.

2. De-dusting: Air classification technology removes dust without harming fine fibres.

3. Dehairing: Eliminates the guard hairs, the coarser guard hairs from the fine cashmere.

4. Fiber Analysis: Optical scanning technology measures fibre diameter and length.

5. Fine Blending: Precise blending creates consistent batches.

6. Specialized Carding: Modified carding equipment processes fine fibres.

7. Gentle Spinning: Low-tension spinning preserves the softness of recycled cashmere.

These machines can recycle high-value cashmere scraps, yarn leftovers, and piece goods, recovering a luxury fibre that would otherwise go to waste.

The impact of textile recycling equipment extends far beyond waste reduction:

· Water Conservation: Recycling one ton of textiles saves up to 20,000 gallons of water

compared to virgin production.

· Energy Savings: Recycling fibres typically requires 50-75% less energy than making new ones.

· Chemical Reduction: Fewer dyes and process chemicals enter the environment.

· Input Material: What textiles will you be processing most frequently?

· Production Capacity: How many daily tons do you want to process?

· Space Constraints: What is your building's size footprint?

· Energy Consumption: What are the costs of operation?

· Output Quality Requirements: What will be the ultimate use for your recycled fibres?

Expandable modular systems are usually the most flexible choice for new facilities in the recycling business.

Ready to take the plunge into textile recycling? Here's where to start:

1. Audit Your Existing Waste Stream: Understand what textiles you send out.

2. Set Clear Objectives: Decide what you want to achieve through recycling (waste reduction, material recovery, etc.).

3. Research Equipment Options: Contact manufacturers that deal with your specific material types.

4. Consider Space and Infrastructure: Ensure your facility has equipment and process flow space.

5. Train Your Team: Effective operation and maintenance are paramount.

With the proper equipment and procedures, you can transform textile waste from a liability into an asset, benefiting the environment and possibly even saving money.

As the global textile waste increases, recycling equipment will become more and more critical as we move towards a circular economy. Whether you recycle vintage clothing, hemp fibres, wool trimmings or high-end cashmere, learning about how this advanced system operates is the first step towards adopting effective recycling solutions for your business.