Since established, Xinjinlong Machinery aims to provide outstanding and impressive solutions for our customers. We have established our own R&D center for product design and product development. We strictly follow the standard quality control processes to ensure our products meet or exceed our customers' expectations. In addition, we provide after-sales services for customers throughout the whole world. Customers who want to know more about our new product textile baling machine manufacturer or our company, just contact us.

This decision can only be made by a pediatrician or a pediatric dentist. * Please contact the manufacturer if the bottle label does not provide information about fluorine. Mr. Deal says the company or its dealers know the level of fluoride in the water and will let you know. The Bottementif bottle will not reveal the level, Dr.

HP LaserJet Enterprise MFP M527f fullin-You need a choice for a larger office, then HP LaserJet Enterprise MFP M527f All-a specialist said-in-A printer is exactly what you need. Designed for low energy consumption, this work machine can wake up quickly and be able to enter sleep mode to print a piece of paper in 8 minutes. 5 seconds.

Multi-roller radius exit may exit Bloom; 5. Reduce the cost of continuous casting. Future research will focus on the actual implementation of these rollers and be tested at the continuous casting plant to validate the methodology proposed by the authors. CAM will be used for handling rollers (Computer-aided manufacturingAnd CNC machine tools. Precision Machining is required to ensure the normal operation of the semi-return roll

The company\'s computer control system enables machine tool operators to create twoThree dimensionaldimensional (3D)Machining procedures on engineering drawings or computers-Auxiliary design geometry file. Also, WinMax has a Windows-Based on the operating system. It offers a machining center with double touch-Screen console or one touchScreen console by VM product line, VMX product line, V-Axis product line, HS product line, HMX product line, HBMX product line, TM/TMM product line, TMX product line and DCX product line.

, we set out as reliable Manufacturer and Wholesaler of broad range of since . We provide best and premium quality of Fabric Recycling Machine and much more. Our provided products are made utilizing the best quality component which is procured from reliable retailers of market. In addition, our firm has appointed well-informed experts who develop these products as per industry norms. In addition, we have hired quality controllers to check these products on different industry parameters. Apart from, we offer a wide range of service such as Customized Retrofit Project and Retail Customized Service in different form that meet on clients demandWe have advanced infrastructure that is separated into various section to run the business activities professionally. This infrastructure unit is handled by our accomplished team members. Our professionals work in close synchronization with each other to get the predefined objectives of the firm. In our quality testing unit, we stringently examine each product in complete.

Tags: fiber bale opener, fibre opening machine price, cloth cutting machine for sale, fiber opening machine price, automatic fabric cutting machine

The main function is to loosen old clothes, cloth leftovers, fibers, cotton, textile materials, it can make massive tangled fiber release into small pieces or fasciculate through the tearing, at the same time,it remove the impurities and mixed the cotton in the process of releasing.

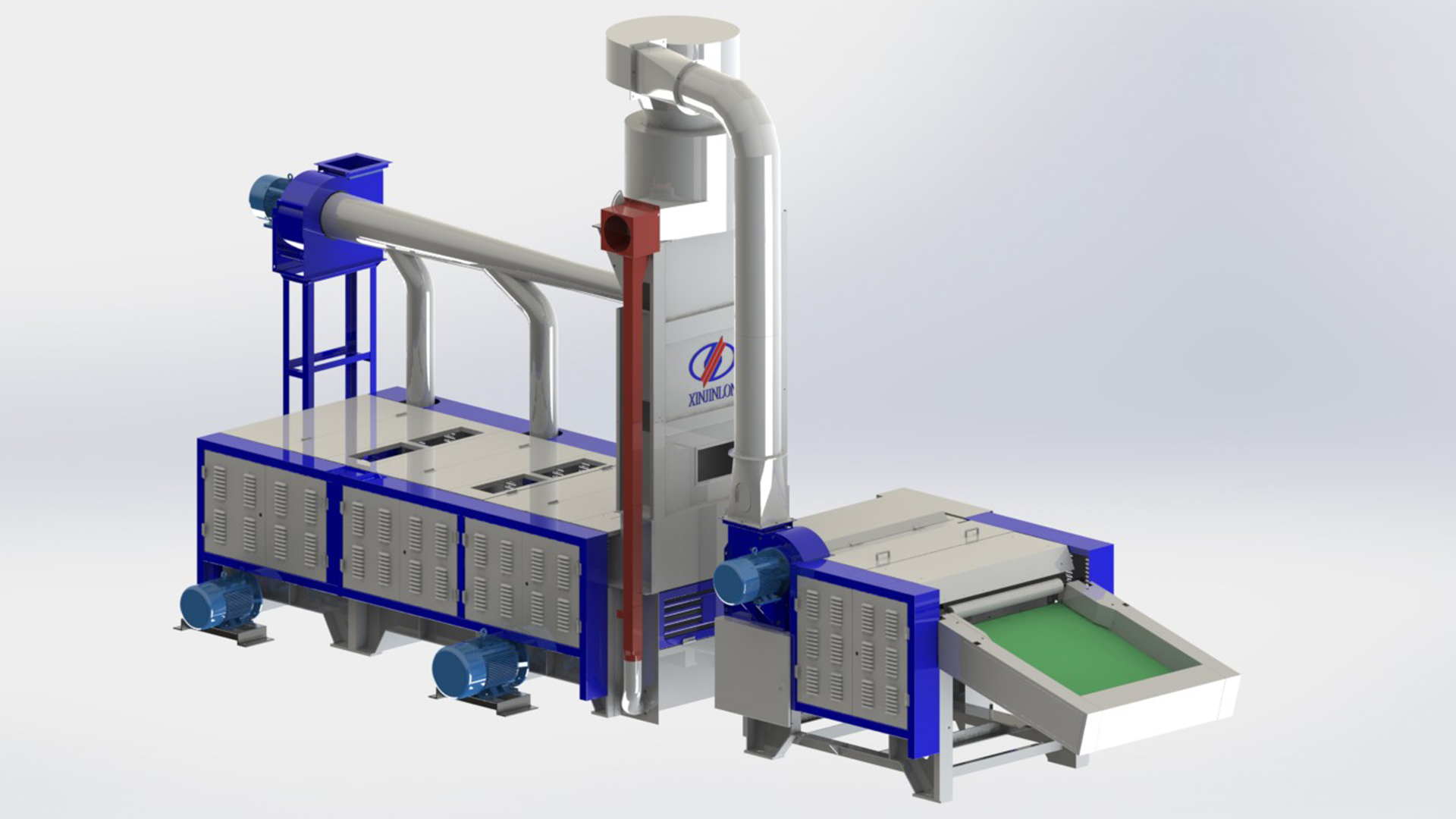

This product is a new product developed by our company in combination with the national environmental protection system and market conditions. This product is widely used and is the replacement product of the bomb cleaning machine.The machine combines the advantages and superior performance of the industry sorting equipment, and according to the national environmental protection department for the discharge and use of the machine inspection specifications, developed environmental protection equipment.Through repeated testing, transformation, equipment has been basically finalized, test and verify that the unit has the advantages of high quality, high yield, low consumption, energy saving, labor saving, safety and environmental protection, is the first choice of fiber processing enterprise technical transformation and equipment update equipment.

Hemp processing production line

Scope of application:

Mainly used for the cleaning and recycling of hemp

Technical Features

1. The new frame structure is scientific and reasonable, safe, reliable in performance, stable in operation and simple in operation

2. Large output, opening, good cleaning effect, low consumption, environmental protection, low noise

3. The application of helical gear reducer has strong adaptability to long-term processing, does not generate heat, and has a long life.

4. Adopt the company's patented product-automatic feeding device, no need for workers to clean up repeatedly, greatly reducing labor intensity

5. Brand-new rack design configuration, gradual processing of raw materials, reducing fiber damage