Since established, Xinjinlong Machinery aims to provide outstanding and impressive solutions for our customers. We have established our own R&D center for product design and product development. We strictly follow the standard quality control processes to ensure our products meet or exceed our customers' expectations. In addition, we provide after-sales services for customers throughout the whole world. Customers who want to know more about our new product carding machine manufacturer or our company, just contact us.

Machine for printing multi-color of disc and floppy disk into six colors for 80 pcs/min. ; In applications that include pressure-for printing machines that roll onto plastic filmSensitive Labels, nameplates, heat transfer and flexible circuits. KASE equipmentSpecializing in decoration turnkey business. The installation can send the product from the molding process to the printing machine, where it is pre-processed, printed and dried, and then automatically packaged or sent to the next operation.

The main function is to loosen old clothes, cloth leftovers, fibers, cotton, textile materials, it can make massive tangled fiber release into small pieces or fasciculate through the tearing, at the same time,it remove the impurities and mixed the cotton in the process of releasing.

This product is a new product developed by our company in combination with the national environmental protection system and market conditions. This product is widely used and is the replacement product of the bomb cleaning machine.The machine combines the advantages and superior performance of the industry sorting equipment, and according to the national environmental protection department for the discharge and use of the machine inspection specifications, developed environmental protection equipment.Through repeated testing, transformation, equipment has been basically finalized, test and verify that the unit has the advantages of high quality, high yield, low consumption, energy saving, labor saving, safety and environmental protection, is the first choice of fiber processing enterprise technical transformation and equipment update equipment.

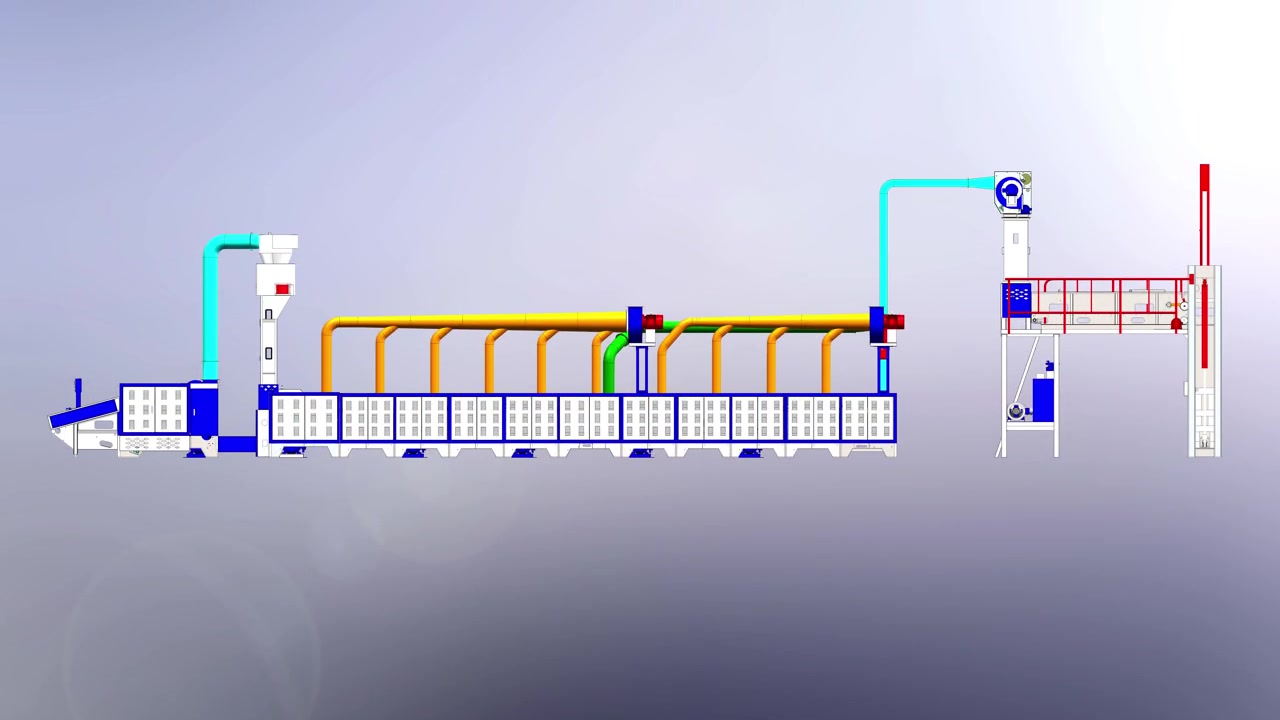

Hemp processing production line

Scope of application:

Mainly used for the cleaning and recycling of hemp

Technical Features

1. The new frame structure is scientific and reasonable, safe, reliable in performance, stable in operation and simple in operation

2. Large output, opening, good cleaning effect, low consumption, environmental protection, low noise

3. The application of helical gear reducer has strong adaptability to long-term processing, does not generate heat, and has a long life.

4. Adopt the company's patented product-automatic feeding device, no need for workers to clean up repeatedly, greatly reducing labor intensity

5. Brand-new rack design configuration, gradual processing of raw materials, reducing fiber damage

Good price textile waste recycling machine in china

This recycling production line is suitable for textile waste other than hemp and knitting. The final product will be used for spinning.

This production line consists of an opener connected to a cotton box, connected to five carding machines, connected to a cotton box, connected to two carding machines, and there will be a set of light sensors on the cotton box to prevent the effect of fire control of the machine. In addition, this connection method will have a dual-purpose effect. When the processed raw materials are used to make felt, the last two sections of the carding machine can be omitted, so that the machine becomes an opening machine and 5 carding machines. Machine, the final product will be made of felt.

The machine is equipped with a casing to isolate the dust generated during the production process, so as to achieve the purpose of protecting the environment and purifying the plant.

Product-cool summer sale 40%-50%.

Tags: fiber bale opener, fibre opening machine price, cloth cutting machine for sale, fiber opening machine price, automatic fabric cutting machine