Since established, Xinjinlong Machinery aims to provide outstanding and impressive solutions for our customers. We have established our own R&D center for product design and product development. We strictly follow the standard quality control processes to ensure our products meet or exceed our customers' expectations. In addition, we provide after-sales services for customers throughout the whole world. Customers who want to know more about our new product textile recycling machine or our company, just contact us.

The position of the needle is variable and has built-in-In storage space. The machine has a perfectly threaded tension adjustable dial control. It also has a drop feed so you can create a quilt pattern in traditional or free form. In order to have a pleasant sewing experience, some other sewing machine manufacturers have asked you to buy a variety of extra things, which is not correct for the brothers.

1 injection molding machine with MP-Sycap controls. After the machine reaches the heat balance, the melt is injected into both the coating and the uncoated cavity. Because the material-Maximum ratio of flow path to wall thickness, 2-The channel with the highest frequency of use is mm depth measurement. Development of internal mold pressure, melting and mold temperature, machine parameters and flow

Industrial Packaging, technical parts. Features: linear shuttle has SteppingMotor control of 0. 01-Reproduction. Six-Layer coex capability. Options: IML, visual inspection, leak detection. Heinz PCM Machinery Co. , Ltd. Machine type: Continuous-Extrusion shuttle extruder capacity: 150 to 440/hour1 or 2 clamping force range: 22 to 112 tons bottle size range: 300 cc to 10 L No★Type blank head: 1 to 5 applications: olefin bottle features: Blow-

Setting up this machine will not get you lost. All in all, this is a good start. The price is right and there are a lot of standard features. Some would argue that it would be better to learn on a non-uterine model. I disagree,; It\'s like learning to drive 1920 Ford cars is better. Rossi has been sewing for more than 30 years.

Founded in the year , we is a well-renowned Manufacturer, and Supplier of a supreme quality range of , etc. Under the fruitful guidance of , we have reached sky high in terms of productivity as well as quality. Located at , we have the latest manufacturing technology coupled with a strong team of highly talented and experienced professionals with decades of experience. It is due to our punctuality & originality in the measurement and quality of our products that we stand outstandingly from our competitors. We also facilitate our customers with customization of the products. We manage bulk consignments efficiently owing to our well-coordinated team efforts and ethics of the company.

Tags: fiber bale opener, fibre opening machine price, cloth cutting machine for sale, fiber opening machine price, automatic fabric cutting machine

The main function is to loosen old clothes, cloth leftovers, fibers, cotton, textile materials, it can make massive tangled fiber release into small pieces or fasciculate through the tearing, at the same time,it remove the impurities and mixed the cotton in the process of releasing.

This product is a new product developed by our company in combination with the national environmental protection system and market conditions. This product is widely used and is the replacement product of the bomb cleaning machine.The machine combines the advantages and superior performance of the industry sorting equipment, and according to the national environmental protection department for the discharge and use of the machine inspection specifications, developed environmental protection equipment.Through repeated testing, transformation, equipment has been basically finalized, test and verify that the unit has the advantages of high quality, high yield, low consumption, energy saving, labor saving, safety and environmental protection, is the first choice of fiber processing enterprise technical transformation and equipment update equipment.

Our company participated in the Shanghai International Textile Exhibition, negotiated cooperation with many foreign companies at the exhibition, and met many familiar customers. We will work harder to bring good products to customers in need

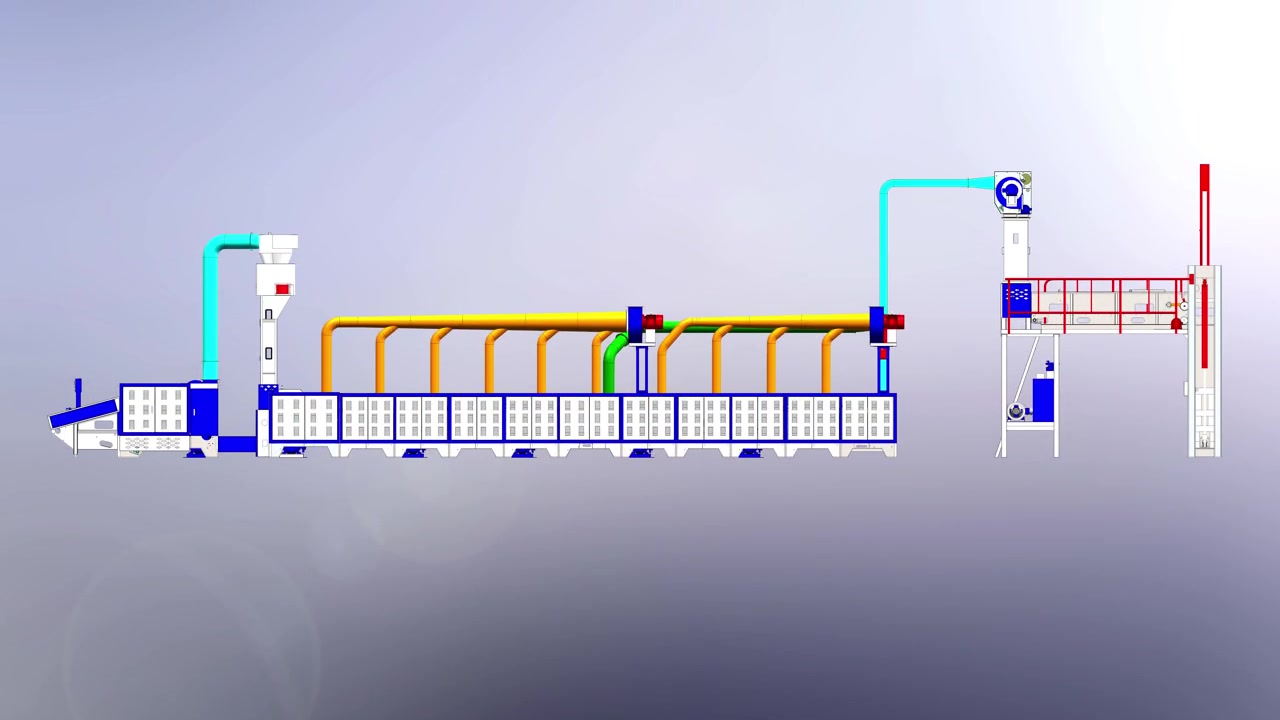

Hemp processing production line

Scope of application:

Mainly used for the cleaning and recycling of hemp

Technical Features

1. The new frame structure is scientific and reasonable, safe, reliable in performance, stable in operation and simple in operation

2. Large output, opening, good cleaning effect, low consumption, environmental protection, low noise

3. The application of helical gear reducer has strong adaptability to long-term processing, does not generate heat, and has a long life.

4. Adopt the company's patented product-automatic feeding device, no need for workers to clean up repeatedly, greatly reducing labor intensity

5. Brand-new rack design configuration, gradual processing of raw materials, reducing fiber damage