Since established, Xinjinlong Machinery aims to provide outstanding and impressive solutions for our customers. We have established our own R&D center for product design and product development. We strictly follow the standard quality control processes to ensure our products meet or exceed our customers' expectations. In addition, we provide after-sales services for customers throughout the whole world. Customers who want to know more about our new product polyester recycling machine or our company, just contact us.

6 U-heating availableForming heating element/segment; * Individual launder sections shall not exceed 5 feet. Manual lift cover or 10 feet. for air-Operating the activated lid; * The Launder cover should provide an effective seal to prevent air entry, thus eliminating the need to install an inert nitrogen/blow cover along the entire length of the washing machine;

Separation equipment can be utilized for a broad range of applications where removal of solids from slurries are necessary. At www.3recycling.com we bring you an extensive range of separation equipment for timely processing of wash water, curd separation, whey separation, effluent streams, etc. The machines are best designed to meet specific requirements. The devices are composed of an original non-vibratory motor that helps in easy separation at a lesser time. The range of device that we feature is optimally designed to remove external contaminations and inclusions from product leaving the product in its purest form.By separating by-products increasing product quality and makes it easy for product classification which in results in easy classification. This machine is equipped with a hi-tech separator used to separate inclusions and impurities from the original substance it helps to obtain the unique product in its purest form maintaining its value. These machines are thoroughly quality tested with the highest quality controlling standards to meet global quality levels. Every machine and its components are tested by experienced professional making sure smooth performance, low energy consumption, and durability.

However, an observation made by Tim Ellis, a senior product expert, involves a completely consistent cycle or pattern: \"We make machines,\" Mr. Ellis said. \"We install the machine. It is under warranty. Work overtime and customers buy parts and services. And then he remade the machine about half. Pass the cycle and get a new warranty.

Fine tuning: 1 liter of nuts in the shell. Reduce the rotor if the damage rate is high. Please lift the rotor if there are too many nuts without housing. For nuts of various sizes, you may have to set it up for large nuts and separate the small nuts that are not housing and then go through the machine again.

is a leading supplier in China. The main business is manufacturing Fabric Recycling Machine, etc. We have established reputation in countries such as where we have core customer bases. Meanwhile, we are well respected by the domestic factories and the customers. We have the confidence, backed by our professional knowledge and experience, to develop the foreign markets for our home enterprises and to open up the Chinese markets for the companies abroad. Nowadays, more and more reputed companies compete in a long-term cooperation with us. That‘s why we can provide our customers with the best quality products, the best price, and the best service. We abide by the principles of honesty, credibility, and mutual-benefit, and do our best to serve clients and customers both at home and abroad. With our top-notch professional knowledge and trading experience, we have seen our market development ability and actual business growth with an increasingly faster pace. We sincerely look forward to working with you to facility your company’s foreign market development and China market expansion. Let’s build a great future together!

Tags: fiber bale opener, fibre opening machine price, cloth cutting machine for sale, fiber opening machine price, automatic fabric cutting machine

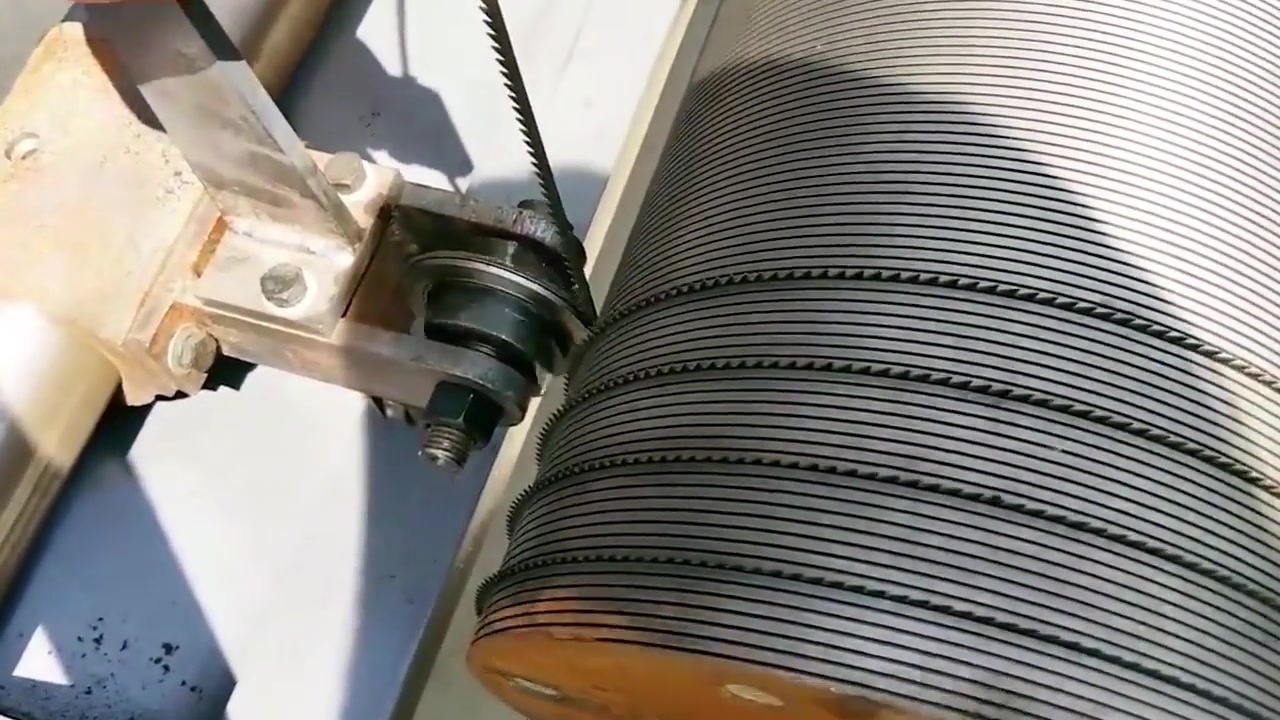

The main function is to loosen old clothes, cloth leftovers, fibers, cotton, textile materials, it can make massive tangled fiber release into small pieces or fasciculate through the tearing, at the same time,it remove the impurities and mixed the cotton in the process of releasing.

This product is a new product developed by our company in combination with the national environmental protection system and market conditions. This product is widely used and is the replacement product of the bomb cleaning machine.The machine combines the advantages and superior performance of the industry sorting equipment, and according to the national environmental protection department for the discharge and use of the machine inspection specifications, developed environmental protection equipment.Through repeated testing, transformation, equipment has been basically finalized, test and verify that the unit has the advantages of high quality, high yield, low consumption, energy saving, labor saving, safety and environmental protection, is the first choice of fiber processing enterprise technical transformation and equipment update equipment.

Hemp processing production line

Scope of application:

Mainly used for the cleaning and recycling of hemp

Technical Features

1. The new frame structure is scientific and reasonable, safe, reliable in performance, stable in operation and simple in operation

2. Large output, opening, good cleaning effect, low consumption, environmental protection, low noise

3. The application of helical gear reducer has strong adaptability to long-term processing, does not generate heat, and has a long life.

4. Adopt the company's patented product-automatic feeding device, no need for workers to clean up repeatedly, greatly reducing labor intensity

5. Brand-new rack design configuration, gradual processing of raw materials, reducing fiber damage