Since established, Xinjinlong Machinery aims to provide outstanding and impressive solutions for our customers. We have established our own R&D center for product design and product development. We strictly follow the standard quality control processes to ensure our products meet or exceed our customers' expectations. In addition, we provide after-sales services for customers throughout the whole world. Customers who want to know more about our new product small carding machine or our company, just contact us.

The key quality attributes must be determined and then the filling machine and process are properly designed. In order to solve complex control tasks, innovative analyzers or sensors are often required. Deep market knowledge of analytical process monitoring equipment helps to find suitable sensors for expected measurement tasks; * Secondly, users should plan their IT structure data management verification during the design phase of the production equipment.

Capsule, bean-to-cup or pump -Isabel HayesMove wrote in tea that this is a problem for coffee fanatics who are trying to replicate the coffee shop experience in a comfortable home. It\'s all about coffee today, not just in a coffee shop. Those who are used to \"thin flat white Go\" are increasingly wanting to replicate the experience at home, an old one when it comes to buying a coffee machine

These energy efficient machines are perfect when doing laundry on a large scale, mainly college laundry, hotel laundry, hospital use of this mechanical service. There are many suppliers and manufacturers of professional washing machine services. in the field of commercial equipment, these machines can be divided into industrial washing machines and commercial washing machines.

In addition, we have heard of production machines and raw milk stations for a while. But Applestone\'s is the first meat product to offer local sustainability, including burger patties, a variety of sausages, steaks and other cuts of beef, and even pet food. Each machine can hold up to 240 items, so Applestone varies depending on the season.

has been committed to the research and development of products, production, sales. Our main products are:Fabric Recycling Machine, etc. We have our own production line and we can provide costomized services. Our products has low price and good quality. It's very popular on all platforms.

Tags: fiber bale opener, fibre opening machine price, cloth cutting machine for sale, fiber opening machine price, automatic fabric cutting machine

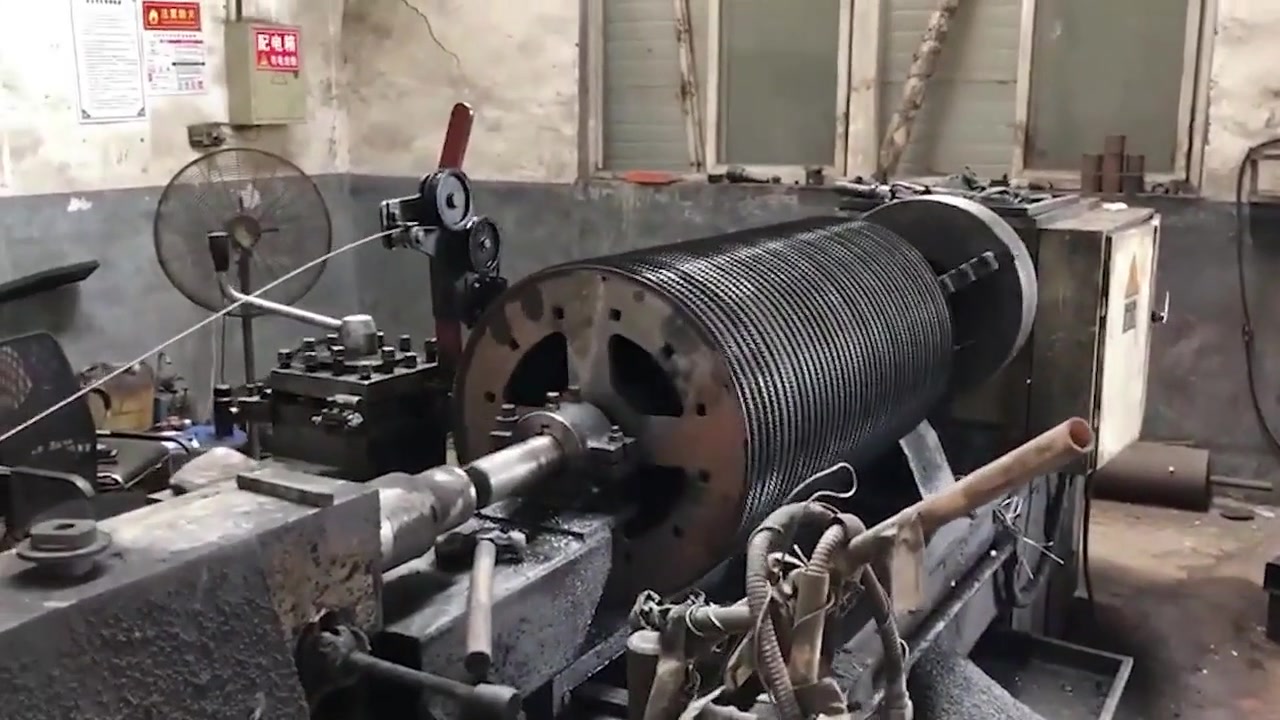

The main function is to loosen old clothes, cloth leftovers, fibers, cotton, textile materials, it can make massive tangled fiber release into small pieces or fasciculate through the tearing, at the same time,it remove the impurities and mixed the cotton in the process of releasing.

This product is a new product developed by our company in combination with the national environmental protection system and market conditions. This product is widely used and is the replacement product of the bomb cleaning machine.The machine combines the advantages and superior performance of the industry sorting equipment, and according to the national environmental protection department for the discharge and use of the machine inspection specifications, developed environmental protection equipment.Through repeated testing, transformation, equipment has been basically finalized, test and verify that the unit has the advantages of high quality, high yield, low consumption, energy saving, labor saving, safety and environmental protection, is the first choice of fiber processing enterprise technical transformation and equipment update equipment.

Hemp processing production line

Scope of application:

Mainly used for the cleaning and recycling of hemp

Technical Features

1. The new frame structure is scientific and reasonable, safe, reliable in performance, stable in operation and simple in operation

2. Large output, opening, good cleaning effect, low consumption, environmental protection, low noise

3. The application of helical gear reducer has strong adaptability to long-term processing, does not generate heat, and has a long life.

4. Adopt the company's patented product-automatic feeding device, no need for workers to clean up repeatedly, greatly reducing labor intensity

5. Brand-new rack design configuration, gradual processing of raw materials, reducing fiber damage