Since established, Xinjinlong Machinery aims to provide outstanding and impressive solutions for our customers. We have established our own R&D center for product design and product development. We strictly follow the standard quality control processes to ensure our products meet or exceed our customers' expectations. In addition, we provide after-sales services for customers throughout the whole world. Customers who want to know more about our new product polyester fiber opening machine or our company, just contact us.

From the budget base to the modern wonder, look for the most indispensable sewing tools. Sewing is very different from the past, and so is the machine on the market today. With so many different sewing machines, it can be daunting to buy one. The machines listed below are worth a try, dividing them by the level of sewing skills, the kind of fit for sewing, and the pros and cons of each category.

It can also be connected to a pipe line. It makes a cup of pure and perfect espresso and makes a cappuccino of the same quality. Put a warning note on the top of the machine for the use of steam valves-Labels that should be attached to all machines. Clear and simple instructions are included.

Sales last year were $531. 8 million. Millon and other major machine tool manufacturers such as Warner and Swasey, Cleveland, gilding and LewisKearney & Trecker and Cross make up the third largest sales in the industry. In addition, hundreds of small private companies in the Midwest are concentrated in Cincinnati, Detroit, Chicago and Cleveland.

The fourth picture shows the hard gear and the rusty bracket on the left. The stepping motor will move counter-clockwise until it touches the stop, which will set the maximum opening throttle. Starting position can be set from there. The management prototype is very simple. No generator. The natural gas carburetor does not have a choke and works differently from the gasoline carburetor.

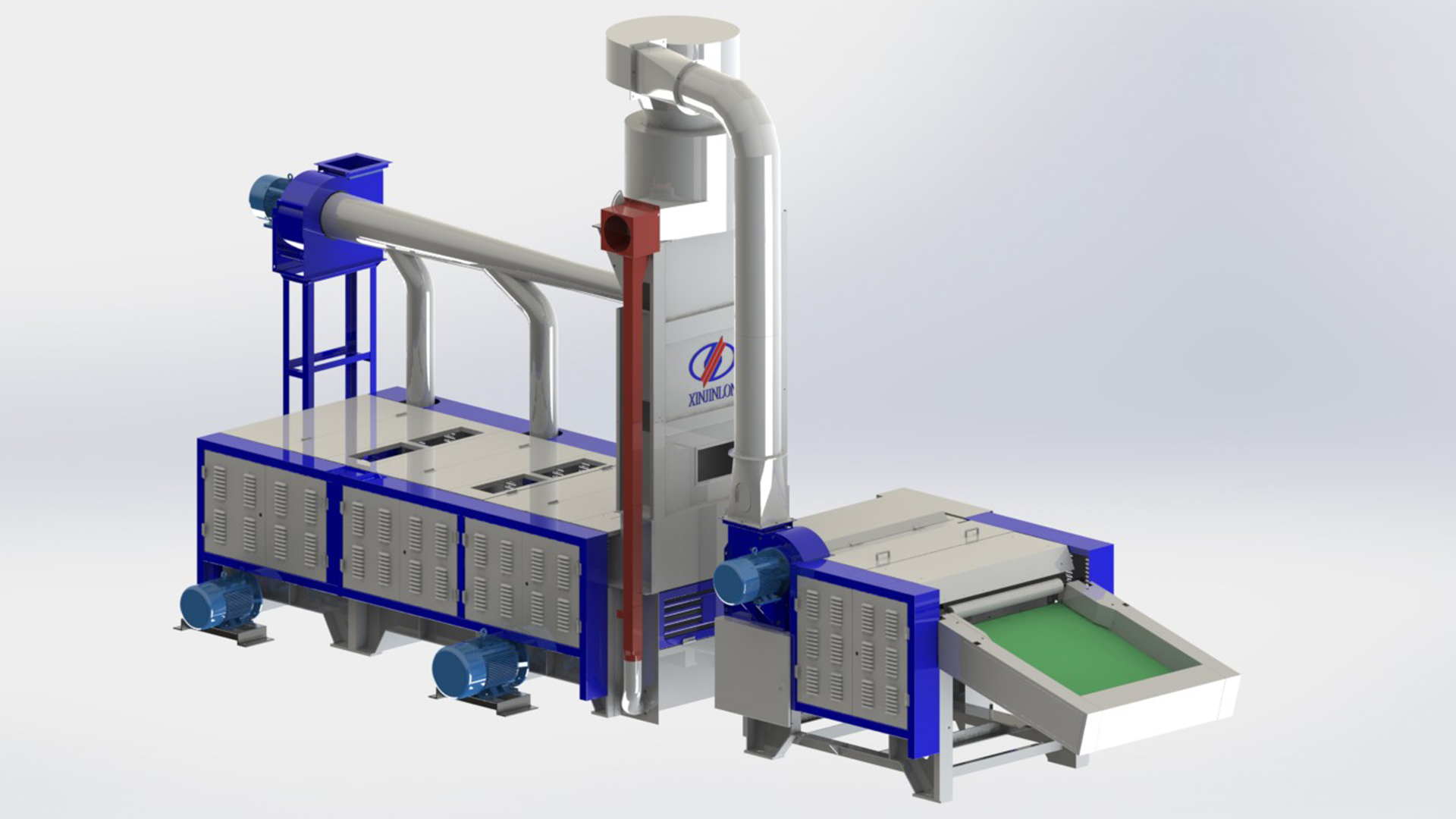

established in , is a professional manufacturer engaged in the research, development, production, sale and service of Fabric Recycling Machine. We are located in with convenient transportation access. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has introduced a series of advanced equipment and we have passed ISO9001 certification, and obtained High-tech Enterprise certificate. Selling well in many cities and provinces around China, our products are also exported to clients in such countries and regions as . Except our own products, we provide OEM services and accept customized order as well. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We sincerely welcome friends from all over the world to visit our company and cooperate with us on the basis of long-term mutual benefits. We are looking forward to receiving your enquiries soon.

Tags: fiber bale opener, fibre opening machine price, cloth cutting machine for sale, fiber opening machine price, automatic fabric cutting machine

The main function is to loosen old clothes, cloth leftovers, fibers, cotton, textile materials, it can make massive tangled fiber release into small pieces or fasciculate through the tearing, at the same time,it remove the impurities and mixed the cotton in the process of releasing.

This product is a new product developed by our company in combination with the national environmental protection system and market conditions. This product is widely used and is the replacement product of the bomb cleaning machine.The machine combines the advantages and superior performance of the industry sorting equipment, and according to the national environmental protection department for the discharge and use of the machine inspection specifications, developed environmental protection equipment.Through repeated testing, transformation, equipment has been basically finalized, test and verify that the unit has the advantages of high quality, high yield, low consumption, energy saving, labor saving, safety and environmental protection, is the first choice of fiber processing enterprise technical transformation and equipment update equipment.

Hemp processing production line

Scope of application:

Mainly used for the cleaning and recycling of hemp

Technical Features

1. The new frame structure is scientific and reasonable, safe, reliable in performance, stable in operation and simple in operation

2. Large output, opening, good cleaning effect, low consumption, environmental protection, low noise

3. The application of helical gear reducer has strong adaptability to long-term processing, does not generate heat, and has a long life.

4. Adopt the company's patented product-automatic feeding device, no need for workers to clean up repeatedly, greatly reducing labor intensity

5. Brand-new rack design configuration, gradual processing of raw materials, reducing fiber damage